ADVANTAGES

Reduce the cycle time

Increase the injection produductivity

Localized temperature control

Hardnesses up to 54 HRC

Allows milling, polishing, texture, welding, among others

Allows coating – nitriding, PVD, etc.

Repair and redesign of parts and components

SERVICES

DESIGN

- Product and part design

- Design for manufacturing

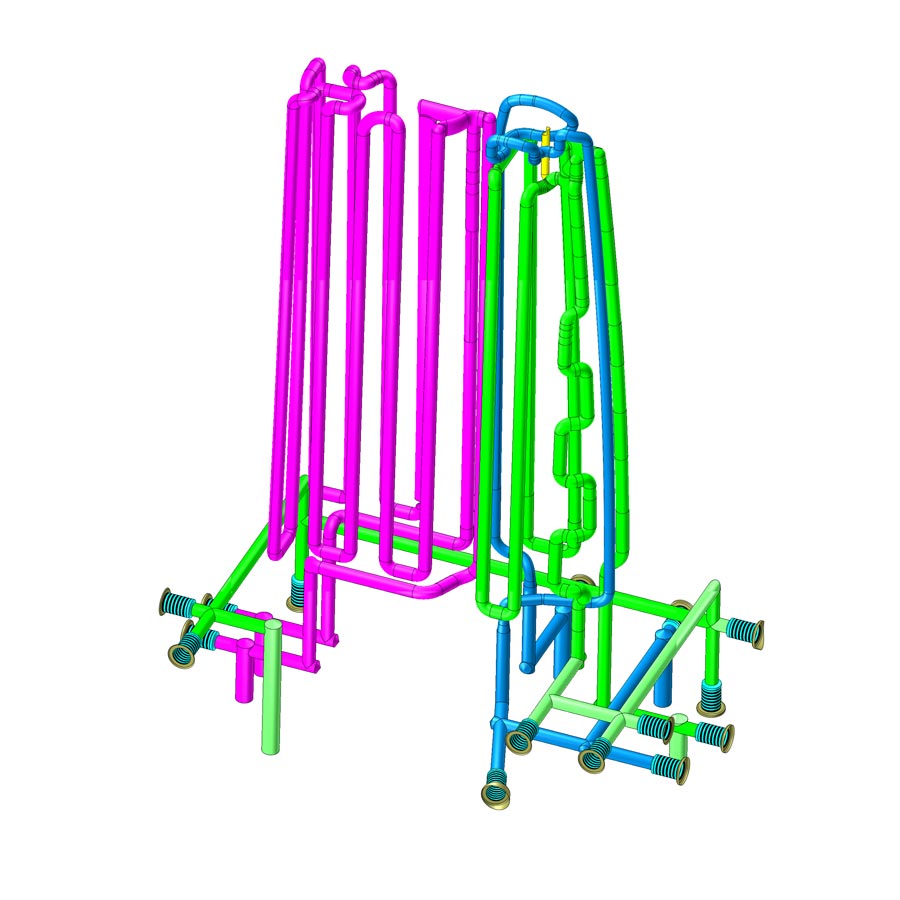

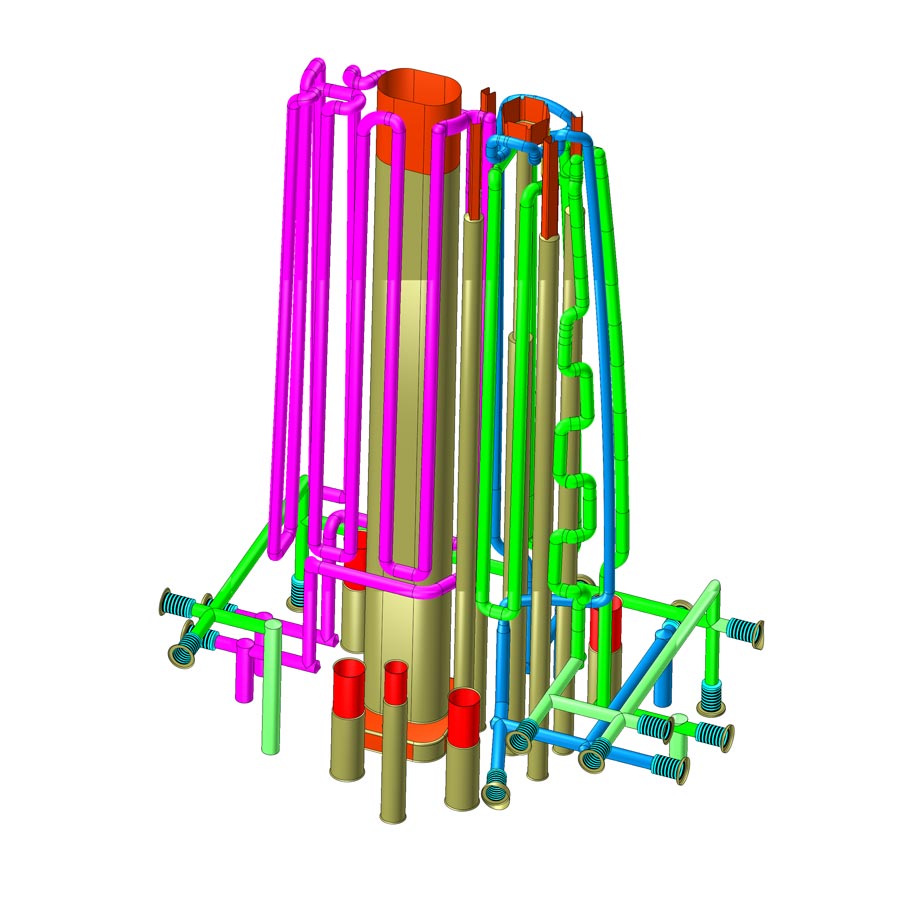

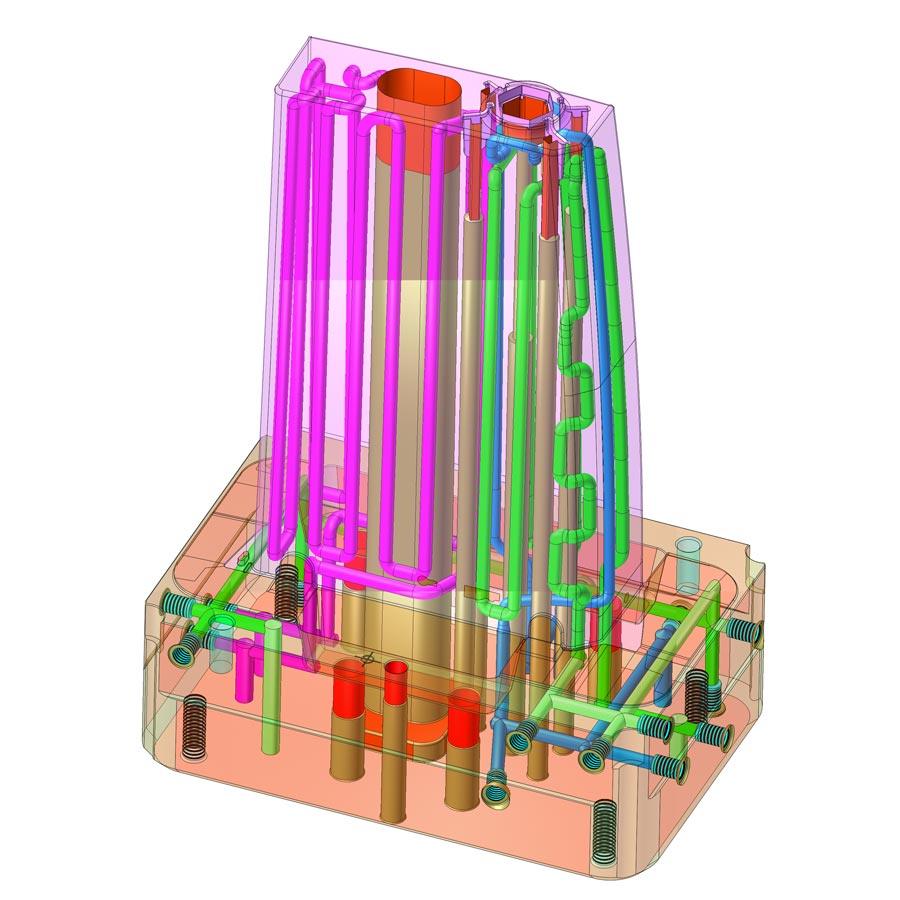

- Conformal channel design

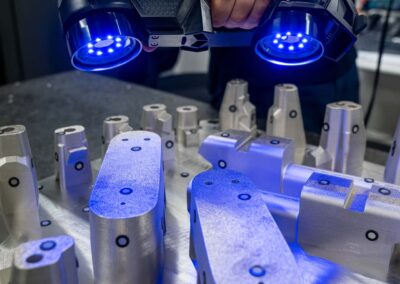

- Reverse engineering (3D scanner)

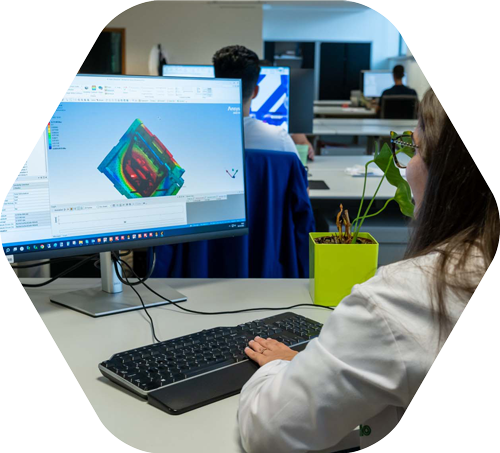

SIMULATION

-

Rheological simulation

-

Structural simulation

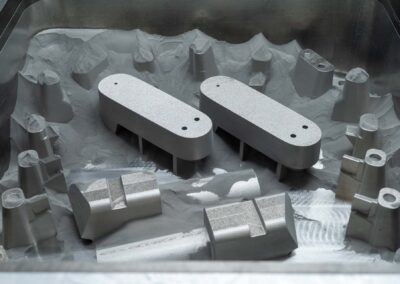

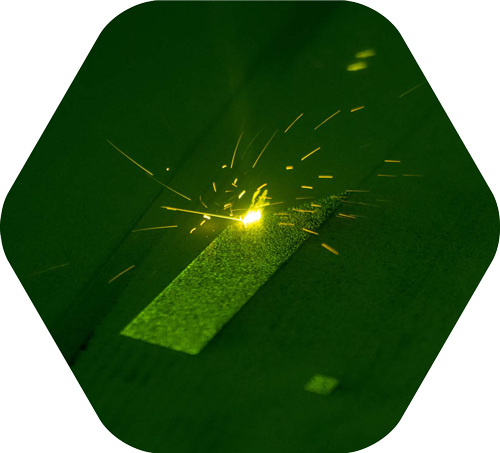

ADDITIVE AND HYBRID

MANUFACTURING

FINISHING

-

Heat treatment

-

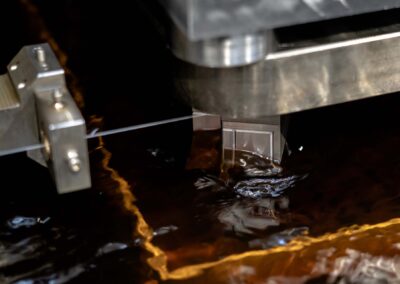

Milling / EDM

-

Sand blasting

-

Technical and high-gloss polish

SEPARATION OF PARTS

LENDING OF METAL BASES FOR MACHINING

MAINTENANCE OF PARTS WITH CONFORMAL COOLING CHANNELS

REPAIR OF PARTS AND COMPONENTS

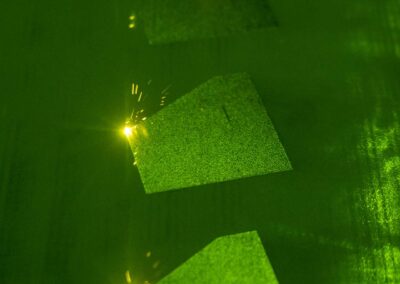

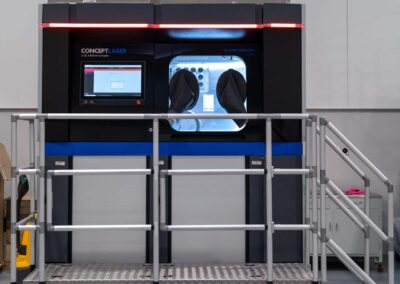

Additive Manufacturing Unit

With a modern architecture, the construction of the building and the acquisition of equipment represented an investment of three million seven hundred thousand euros, with community support in the amount of seven hundred and fifty thousand euros.

This new unit enables an innovative production process, more competitive and able to offer differentiated products.

Watch the video

Visit us!

If you would like to visit our Additive Manufacturing Unit, please contact us.